Porduct Details

Copper Pipes

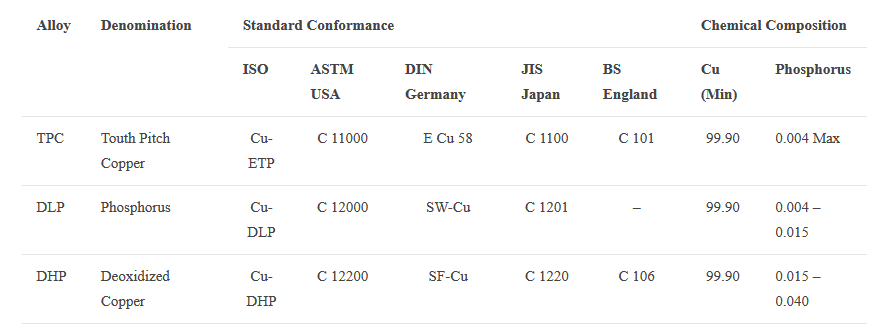

To satisfy the market demand, copper tubes are produced in three groups of TPC, DHP and DLP with following applications:

CSP, as the most reputable manufacturers of copper tubes in Iran, is manufacturing world-class seamless, thin-wall copper tubes according to the international standards. Combination of high-quality precision machinery and advanced digital control system has made CSP enable to keep tighter dimensional tolerances and to meet the most stringent standards. In addition, the carefully controlled annealing process introduces a new level of cleanliness for the tubes.

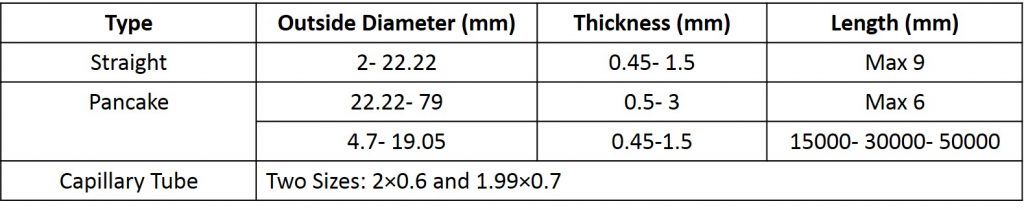

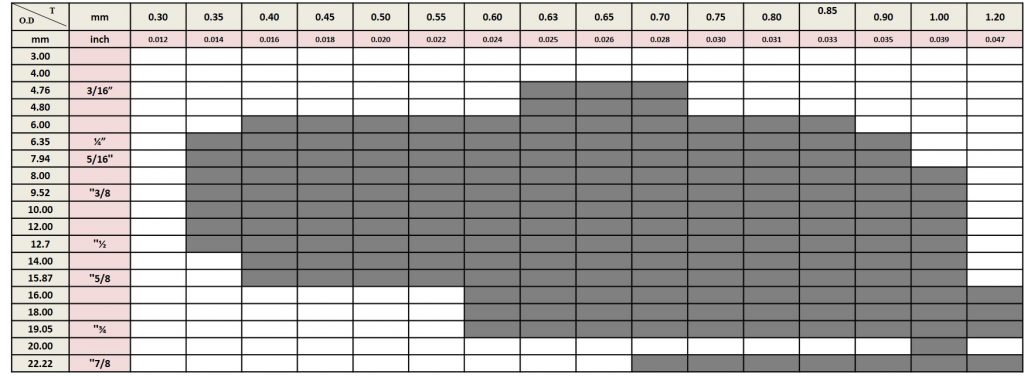

Following two main groups of tubes can be manufactured in the CSP plant.

- – Smooth surface copper tubes.

- – Inner grooved copper tubes.

Inner grooved tubes can be used in superior residential and commercial air conditioning units. The purpose of these tubes is to enhance heat transfer between the medium inside and outside of the tube by increasing the inner contact surface. These seamless drawn tubes increase the efficiency of heat exchangers. The seamless drawn tubes are enhanced by applying a special inner tool (die) while drawn to the final dimension.

TPC copper pipe: These copper tubes have excellent electrical and thermal conductivity, and are mainly used in electrical applications especially as cab le shoes.

DLP & DHP copper pipe: Good workability, draw-ability, high heat conductivity and weldability are the main characteristics of this category of copper tubes, w hich make them excellent to be used in HVAC (heating, ventilation and air conditioning) systems and industrial heat exchangers.

Heat exchangers are used to transfer heat between two fluids and are commonly used in water heaters and air conditioning systems.

Chemical composition and standard conformance for brass sections are as the following table.

DIN Standards

DIN 1787, DIN 178 5, DIN 1754-1, DIN 1754-2, DIN 17671-1, DIN EN 12449, DIN EN 12451, DIN EN 12735-1, DIN EN 12735-2,

ASTM Standards

ASTM B111M-11, ASTM B75/B75M-11, ASTM B280-08, ASTM B395/B395M-08, JIS H 3300

JIS Standards

JIS H 3300

BS Standards

BS 2871-2:1972, BS 2871-3:1972, BS EN 12449:1999, BS EN 12451:1999, BS EN 12735-2:2010